Smarter Design. Lower Cost. Smaller Footprint.

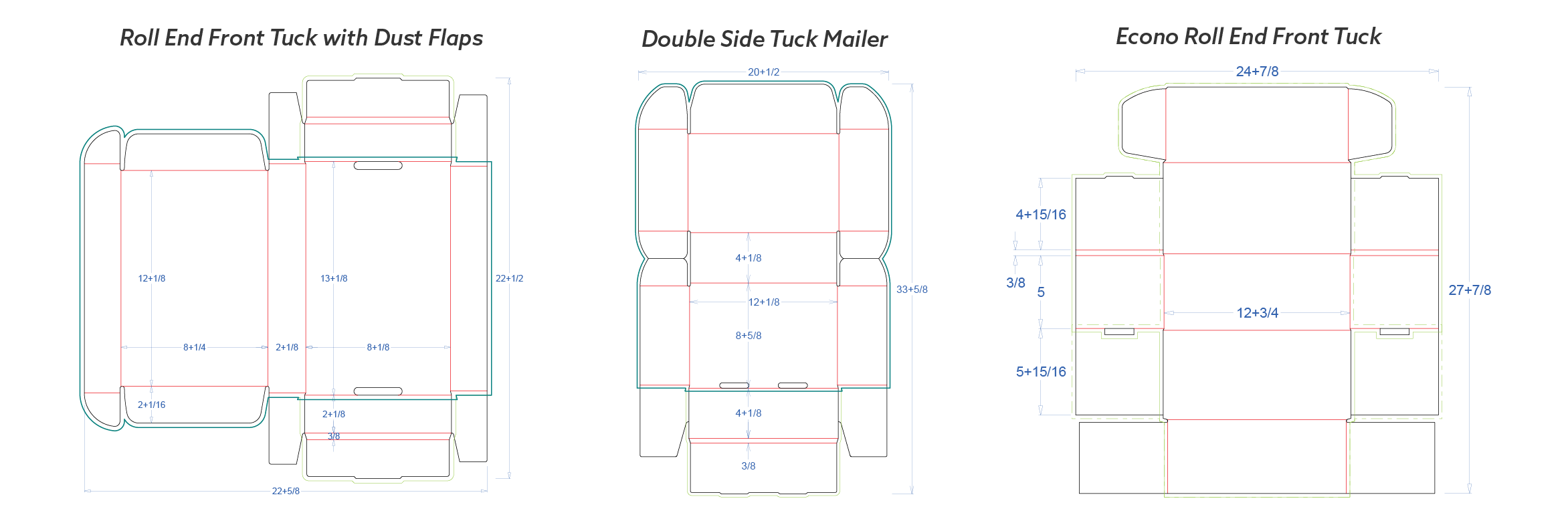

For many brands, a standard Roll End Front Tuck mailer box feels like the safest choice. It is familiar, protective, and widely used. But “standard” does not always mean optimized. With over 40+ design options, we offer solutions that reduces material usage, lowers cost, and supports sustainability goals without sacrificing performance.

The Double Side Tuck Mailer and the Econo Roll End Front Tuck were both developed with that mindset. Each style rivals traditional mailers while using less overall square footage, resulting in lower pricing and a smaller environmental footprint.

Rethinking the Traditional Mailer

Traditional roll end front tuck mailers are dependable, but their layouts are not always the most material-efficient. Depending on the box dimensions, excess board can be built into the design simply due to how the dieline is structured.

More board usage means more source material, more waste, and often a higher per-unit cost. For brands shipping at scale, even small reductions in square footage per box can have a measurable financial and environmental impact. That is where smarter structural design makes the difference.

The Double Side Tuck Mailer, was innovatively designed to rival the leading mailer style while using less material overall. Its economically engineered layout trims unnecessary board usage while maintaining exceptional structural integrity.

The Double Side Tuck Mailer, was innovatively designed to rival the leading mailer style while using less material overall. Its economically engineered layout trims unnecessary board usage while maintaining exceptional structural integrity.

Instead of a single front tuck, this style features double flaps that neatly tuck into each side of the box. The result is a secure closure that feels intentional and polished. From a customer perspective, the unboxing experience is clean and easy. From a brand perspective, the additional flap space provides more room for creative graphics, messaging, or interior print moments.

Operationally, it’s just as practical. It ships flat to streamline fulfilment storage and transportation, helping reduce warehouse footprint. Its self-locking system and easy assembly process simplify packing workflows and save time on the line.

The key advantages of the Double Side Tuck Mailer include:

• Reduced overall material usage compared to traditional layouts

• Strong structural performance

• Additional surface area for graphics and branding

• Flat shipping and efficient assembly

It is a balanced solution that supports both cost control and sustainability goals.

If your priority is pushing material efficiency even further, the Econo Roll End Front Tuck offers a highly strategic alternative.

If your priority is pushing material efficiency even further, the Econo Roll End Front Tuck offers a highly strategic alternative.

This economical mailer solution is designed with the most efficient use of material space in mind and can generate up to 30% less waste than a traditional mailer. By reworking how the box is laid out on the sheet, this style minimizes excess board and reduces scrap.

The savings become even more impactful when your box depth and width are identical or very close in size. In those cases, the layout becomes especially efficient, using less material and delivering a lower overall cost.

The Econo mailer is ideal for brands that:

• Ship square or nearly square products

• Want to reduce board consumption and waste

• Are looking for the most cost-effective structural option

• Prioritize sustainability through material reduction

It is a straightforward, smart design that proves efficiency can directly support both your budget and your environmental objectives.

Comparing DSTM and Econo to Traditional Mailers

Both the Double Side Tuck Mailer and the Econo Roll End Front Tuck outperform traditional mailers in one critical area: material efficiency. By reducing total square footage and optimizing layout, they lower source material consumption and shrink your packaging footprint.

The Double Side Tuck Mailer offers a strong alternative to the standard mailer experience, with added branding flexibility and a refined tuck closure. The Econo mailer focuses on maximizing yield and minimizing waste, particularly for square dimensions.

In both cases, the result is the same. Less board. Lower cost. Smaller footprint.

If you are currently using a traditional mailer, it may be worth evaluating whether your dimensions could translate into a more efficient structure. A simple design shift could unlock meaningful savings while reinforcing your sustainability commitments.